How in-water vaccination could be valuable for pig farmers

In-water vaccination is still regarded as quite a novel technique in pig production. However, more producers are considering how medicines delivered through drinking water could save them time and money.

Dave Hodson, from Rosehill, says the ability to effectively immunise large numbers of pigs without having to physically handle each individual animal offers significant advantages.

Vaccinating all young piglets at weaning has become a routine task on most pig units, and for respiratory diseases, such as porcine reproductive and respiratory syndrome (PRRS), enzootic pneumonia (EP) and porcine circovirus (PCV2), technology such as needle-free injection and multi-valent vaccines are delivering innovative, time-saving solutions.

However, controlling enteric disease in post-weaned piglets often relies on in-feed treatments, antibiotics or zinc oxide medication. Used strategically under veterinary guidance, these therapies will effectively control post-weaning diarrhoea (PWD). However, with producers under continued pressure to reduce antimicrobial use and a zinc ban now in place, vets and pig producers are exploring alternative ways to prevent PWD.

Mr Hodson has been working with several pig producers to help establish effective in-water vaccination programmes to protect newly weaned piglets against E. coli scours. “Using the Coliprotec™ vaccine, these farms are demonstrating how enteric health can be improved in the rearing herd when piglets are vaccinated via their drinking water, between 18 and 25 days of age. Using in-water vaccines eliminates the need for another injection around weaning and provides protection against PWD caused by ETEC F4 and F18 E.coli ,” says Mr Hodson.

Dave Hodson, Rosehill

Implemented with relative ease and minimal labour input, the Coliprotec vaccination strategy has shown good outcomes in terms of disease control and performance, with pigs proven to achieve up to an extra 2kg1 of slaughter weight and reaching market weight seven days sooner2.

Around 90% of all vaccines given to commercial poultry are delivered via the drinking water, and vaccinating young pigs this way is a viable option too according to Mr Hodson. It offers a stress-free alternative compared to more conventional methods, with the technology and equipment now available to farmers, making automatically dosing drinking water with a vaccine, relatively simple and cost-effective.

The in-water techniques and management protocols routinely used to medicate commercial laying hens and broilers have cut down labour requirements and improved dosing accuracy.

“Pig producers could certainly benefit from this approach, but I’d encourage those wanting to try in-water vaccination for the first time to invest time in understanding how to implement this technique successfully,” advises Mr Hodson.

Rosehill has worked alongside several pig producers to implement a similar in-water vaccination protocol to the process they use with their poultry clients. They say in-water vaccination is a very effective tool. However, Mr Hodson is quick to point out the vital importance of vaccine care on farm, and how storage/handling, water quality, drinker and pipeline hygiene, alongside compatibility with nutraceuticals can affect live vaccine performance and ultimately livestock health.

Top tips on successful in-water vaccination

Storage facilities

- All live vaccines should be refrigerated between 2 and 8 degrees Celsius. Use a minimum and maximum thermometer inside the fridge and undertake frequent inspections – at least once a day

- Any contamination or adverse temperature changes will compromise vaccine viability, which could reduce the immune response and lead to a disease outbreak

Water line hygiene

- Water lines must be clean and the supply must have a neutral pH between 6.8-7.2 before the vaccine is introduced and for the duration of treatment

- Ensure drinking water does not contain contaminants, antimicrobials or a heavy mineral content, such as high iron levels, which are common with borehole supplied sources – test water quality if unsure

Sanitising agents

- The presence of any sanitising chemicals, such as chlorine and hydrogen peroxide, even at low levels, will kill-off the viral or bacterial constituents of a live vaccine

- Organic acids can also have a damaging effect and so should be removed at least 24 hours before vaccination

- Sanitising agents or acidifiers used to control biofilms/microbial activity must be completely flushed out of the water system before a live vaccine is introduced

Water stabiliser

- Use a water stabiliser, such as AviBlue™, which buffers the aqueous environment and stabilises the pH of the water supply. It contains sodium thiosulfate, which reacts with chlorine causing it to ‘drop out’ of suspension. This creates a safe medium for the vaccine to be mixed into. It also adds a blue tone to the water so stockmen can see that the vaccine solution is being supplied throughout every line

Palatability

- Palatability is more important with pigs than poultry. If the water tastes nice, the pigs readily consume it. Adding an aniseed-flavoured electrolyte to the vaccination solution can increase water uptake in weaners

- Monitor drinking behaviour

- Monitor water consumption to ensure the correct amount of vaccine is within the recommended time frame

Order your free Coliprotec diagnostic pack.

More Materials

Coliprotec

Find out more about how Coliprotec™ live oral vaccine protects piglets against Post-Weaning Diarrhoea (PWD) caused by F4-F18 ETEC.

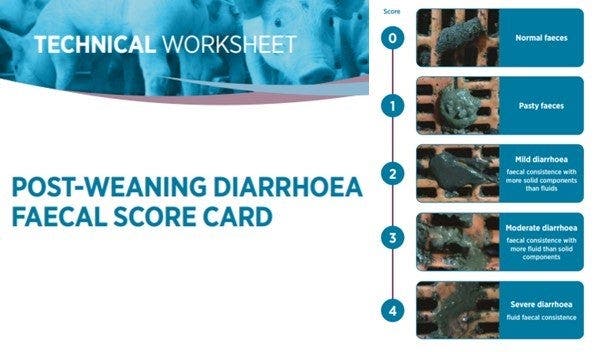

Post Weaning Diarrhoea Faecal Score Card

Download the Post Weaning Diarrhoea Score Card.

Innovative Solutions to Prevent E. Coli PWD in Pigs

E. Coli post-weaning diarrhoea (PWD) is a common issue across farms worldwide and the means for treating it and preventing it are at odds amongst the industry.

- Tokach LM et al J Swine Health Prod 2000 229.

- Purina Mills Purina Mills EACH PRODUCTION PHASE IMPACTS THE NEXT 2015.

- Vangroenweghe F et al 10th European Symposium of Porcine Health Management 2018 254.